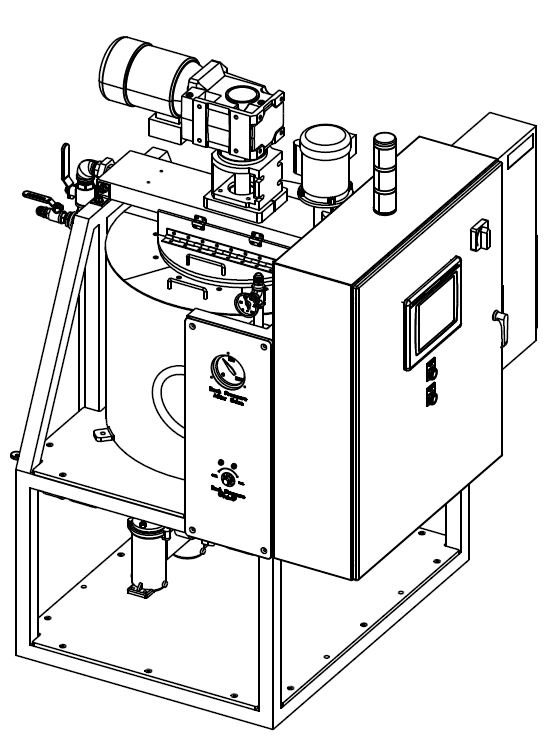

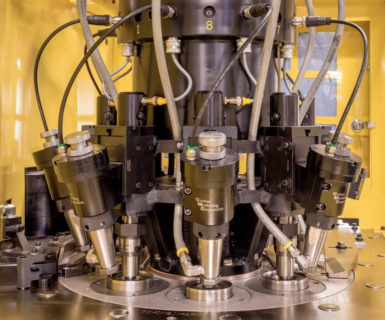

CMC is continuously improving the process, equipment, and business of container End-Lining.

As the world’s foremost supplier of End-Lining equipment, we bring to bear years of industry experience, design expertise, and manufacturing technology which results in world-class performance and reliability.